Growing strong and versatile young plants for your desired cultivation method

Combining the Best of Both Worlds

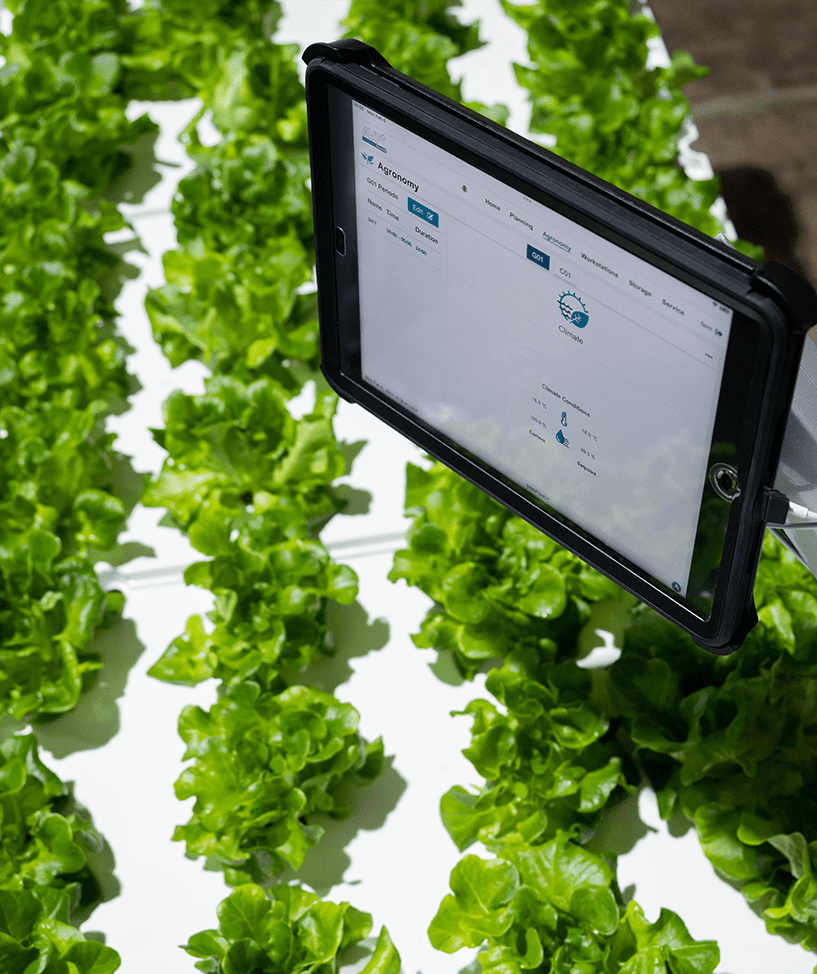

Introducing AVF+ Young Plants – a cutting-edge solution revolutionizing plant propagation and cultivation. This innovative system empowers growers to nurture robust and thriving plants at high densities by meticulously regulating environmental variables such as temperature, light, humidity, and nutrients within an optimal growth environment for young plants.

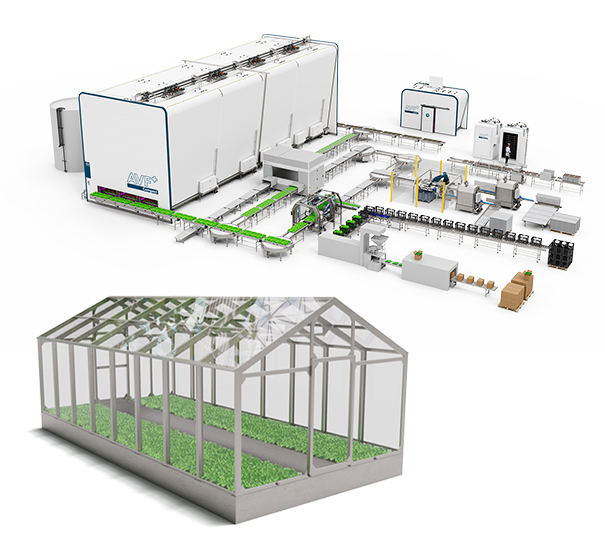

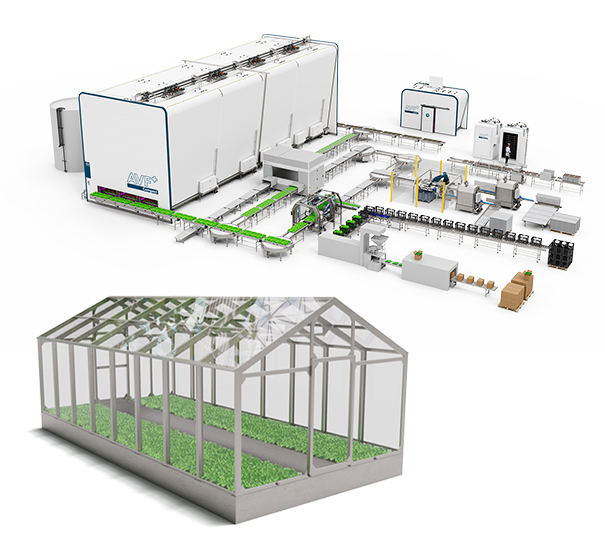

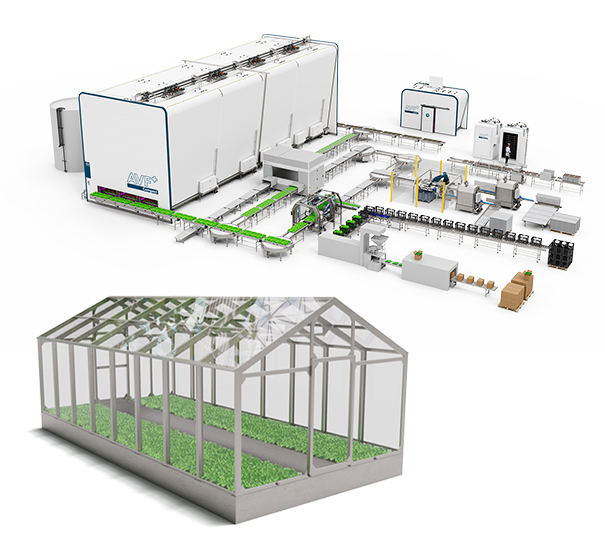

The AVF+ Young Plants consists of automated vertical growing propagation, and for example, greenhouse cultivation. It liberates you from supplier dependencies and shields against potential quality degradation during transportation.

Moreover, it ensures consistent, year-round output and quality, eliminating seasonal limitations.

The AVF+ Young Plants enhances productivity and slashes operational costs, leading to a swift return on investment. It provides the flexibility to explore alternative cultivation methods, all while preparing young plants for seamless transitions. Whether you aim to maximize greenhouse usage, leverage year-round cultivation, or embrace fully automated vertical farming, AVF+ Young Plants offers a versatile solution.

This system's core mission is to optimize propagation and make cultivation cost-effective. With the AVF+ Young Plants, you're experiencing the future of horticulture today, where automation and precise environmental control converge to redefine plant cultivation.

Turn-key AVF+ Young Plants

AVF+ Young Plants

DFT and Processing Equipment

Turn-key AVF+ Young Plants

AVF+ Young Plants

DFT and Processing Equipment

Turn-key AVF+ Young Plants

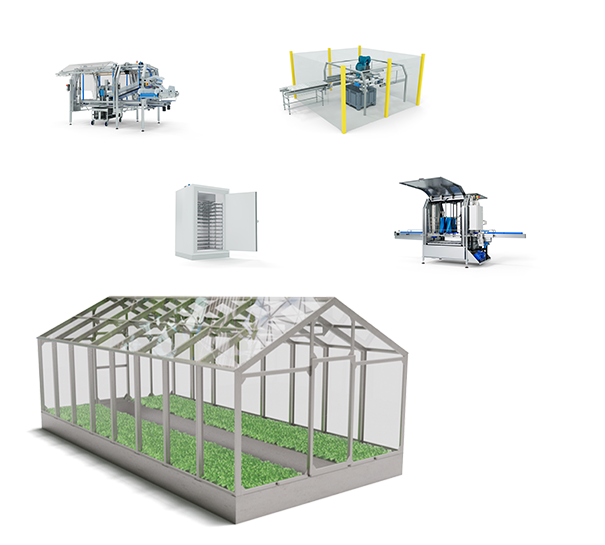

When we integrate AVF+ process equipment into your (existing) AVF+ Hybrid solution, it becomes a comprehensive Turn-key AVF+ Young Plants solution. We will oversee the entire production process, from seeding to packaging. The choice of manual, semi-automatic, or fully automated process equipment will be tailored to your specific needs, considering factors like size and local conditions.

AVF+ Young Plants

Incorporate the AVF+ Young Plants into your current cultivation approach and harness the benefits of this automated vertical farming system designed explicitly for nurturing young plants. Within the climate-controlled chamber of the Compact, precise management of factors such as light, environmental conditions, irrigation, and nutrients ensures the ideal environment for crop propagation. Moreover, the growth cycles are entirely automated, making it a convenient and efficient solution.

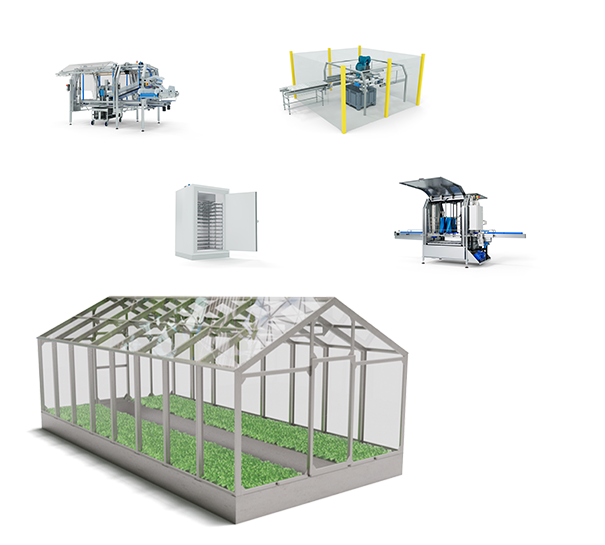

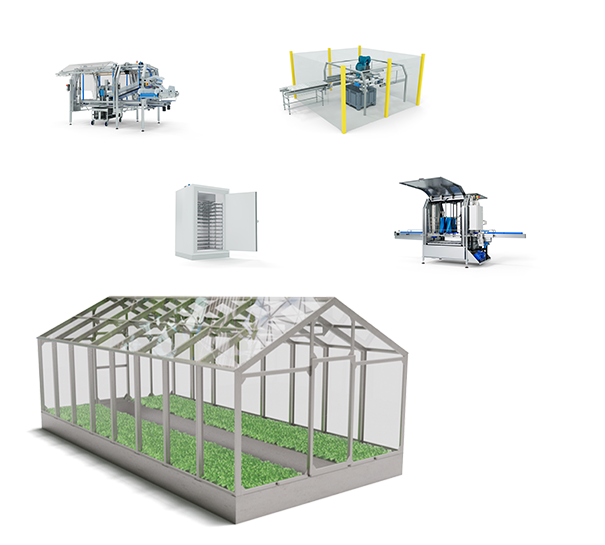

DFT and Processing Equipment

Supercharge your agricultural operations with our DFT (Deep Flow Technique) and top-of-the-line processing equipment, also available as standalone products. You can pick and choose the components that best suit your unique needs. Take control of your farming success and elevate your harvest to new heights.

AVF+ Young Plants

Whether you're a seasoned grower with a greenhouse or a newcomer without, we're here to support you.

You can easily incorporate the AVF+ Compact for precise crop propagation to your cultivation method or start from scratch with our turn-key AVF+ Young Plants with DFT setup with our comprehensive process equipment integration.

However, implementing Artechno's standalone processing equipment for your tailored farming method is also possible.

Automated vertical farming in combination with your Desired Cultivation Method

Year-Round Production

Controlled growing with AVF+ Young Plants provides year-round, high-quality crops by managing environmental conditions indoors, ensuring consistent, climate-independent young plants for versatile cultivation methods.

Increased Yields and Quality

Our unique approach involves propagating plants in a controlled AVF+ cell before transitioning to the greenhouse. This results in stronger, healthier, and higher-yielding crops, ensuring premium quality harvests.

Resource Efficiency

Growing with AVF+ prioritizes resource efficiency. It optimizes water, fertilizer, and energy use through precise automation, reducing crop waste during transport.

Propagate to your Wishes

Experience tailored propagation with a Compact cell. Customize the growth environment to your exact preferences, ensuring optimal crop conditions. Harness the power of precision in propagation with AVF Compact.

-1.png)

Feature #1

Get the Best out of Your Seedlings

.png)

Feature #2

Standalone or a turn-key solution

Feature #3

Processing Line (1)

.png)

Feature #4

Processing Line (2)

Possible Cultivation Solutions

Whether you are an existing or new grower, we've got your back

Artechno's Deep Flow Technique (DFT)

Learn more

Other cultivation methods

Learn moreLet us tell

You more.

- Get in touch with Artechno Growsystems

- Learn more about Automated Vertical Farming

- And any other questions