Medium to large scale automated vertical farming factory, from seeding to packaging

.png)

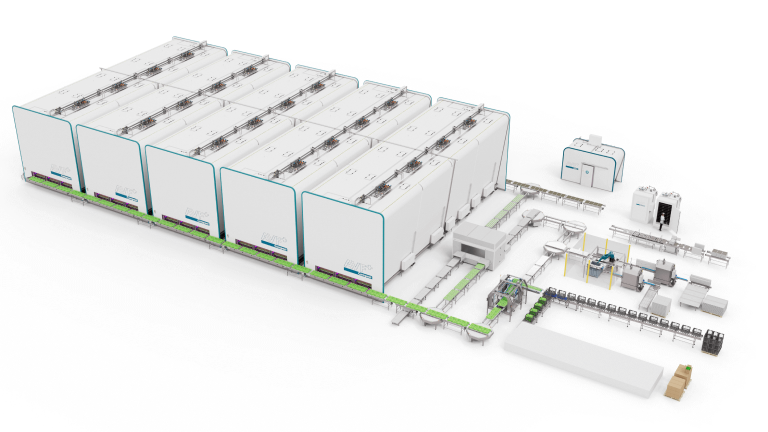

Factory 96-960

.png)

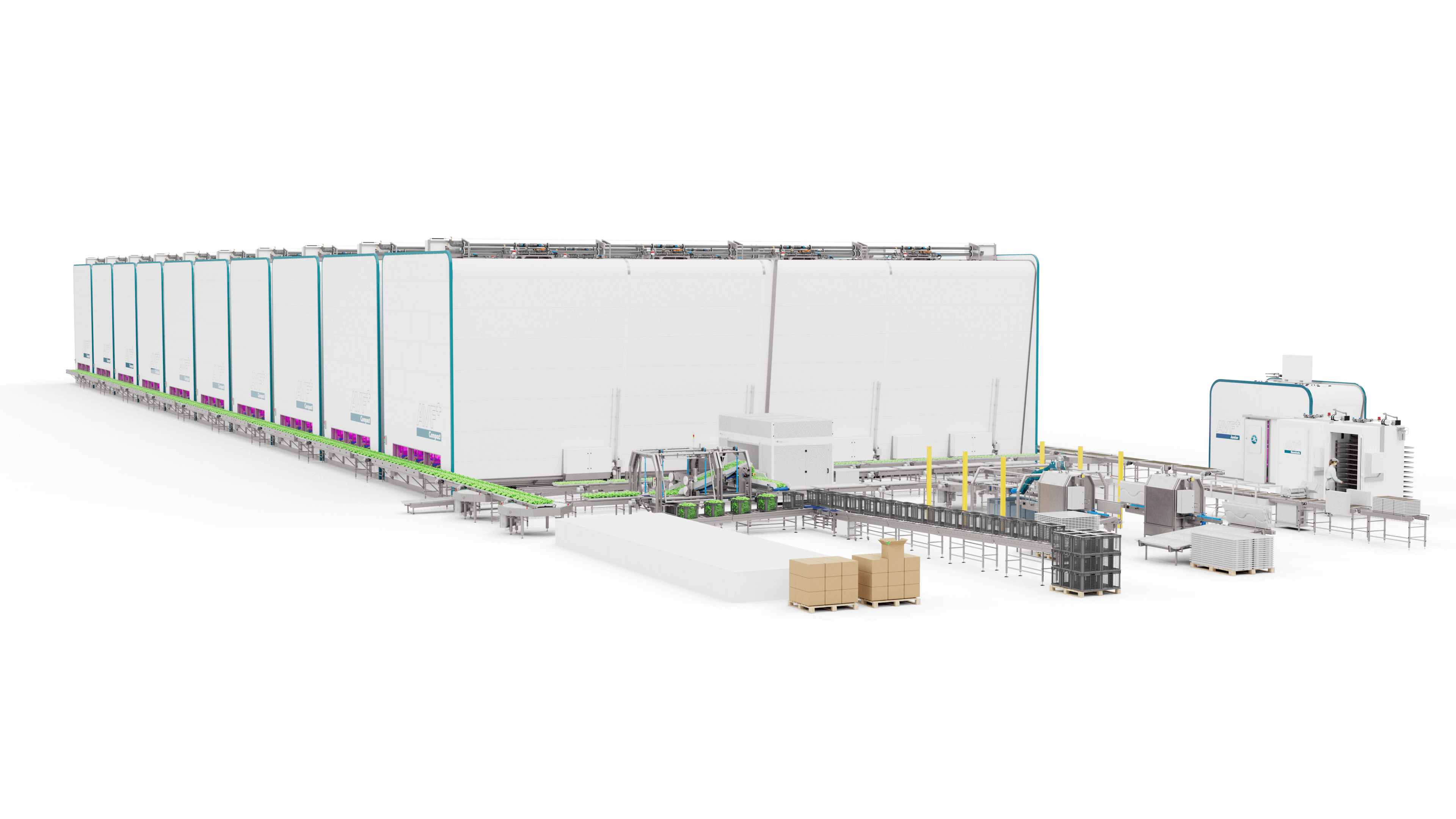

Factory 4.800

.png)

Factory 9.600

.png)

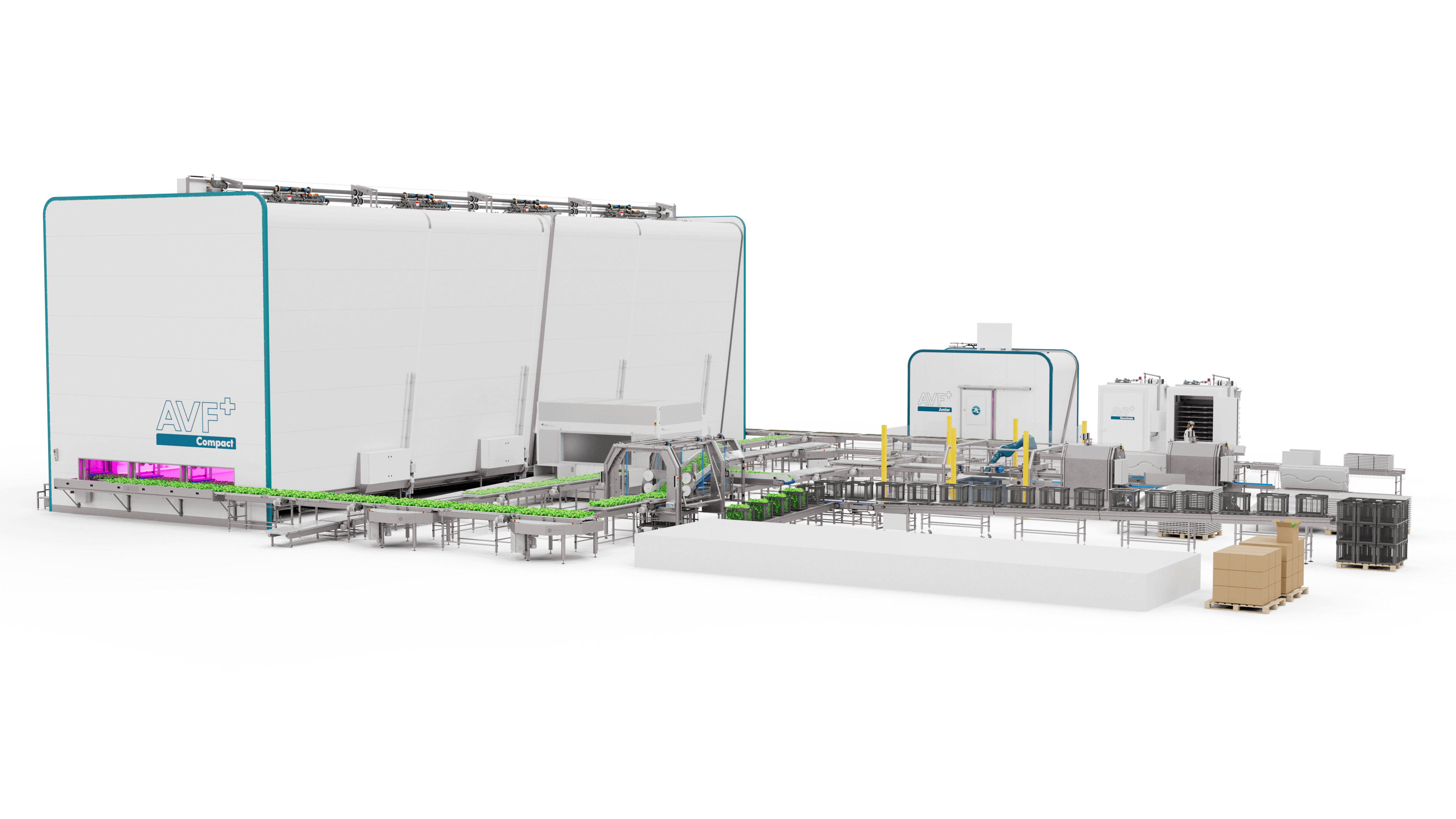

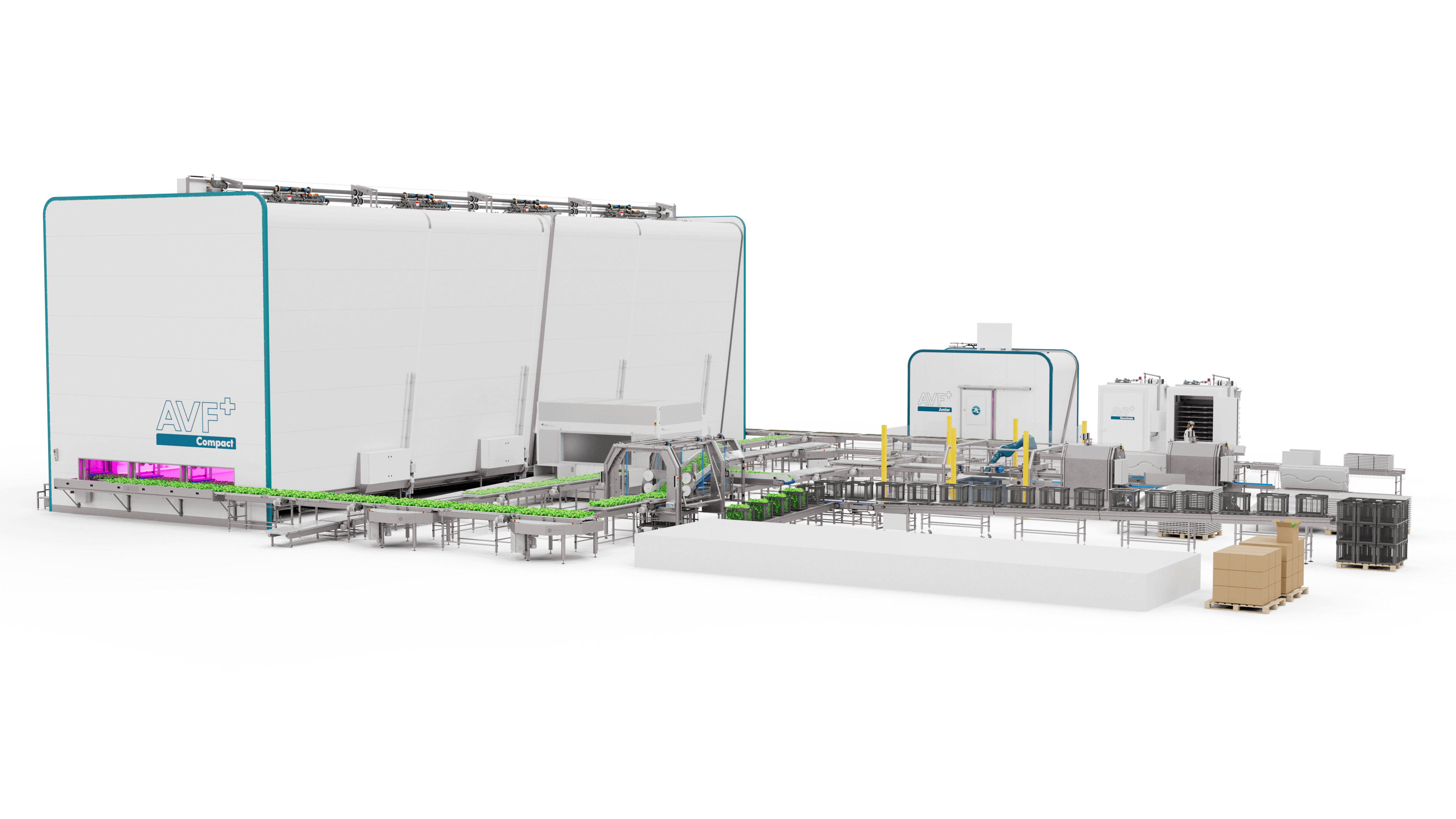

Factory 96-960

.png)

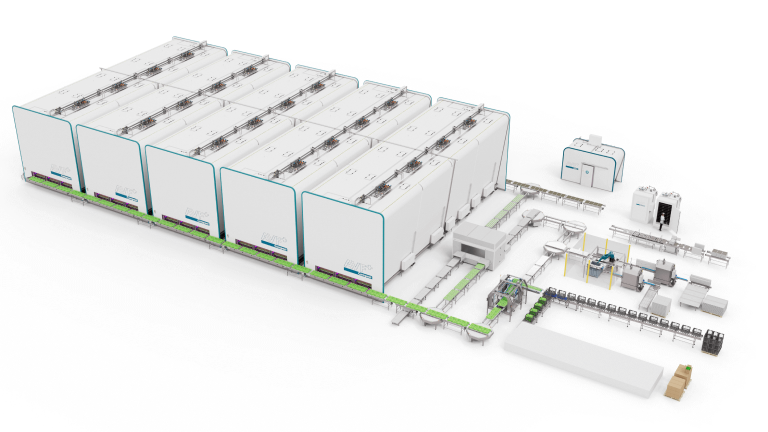

Factory 4.800

.png)

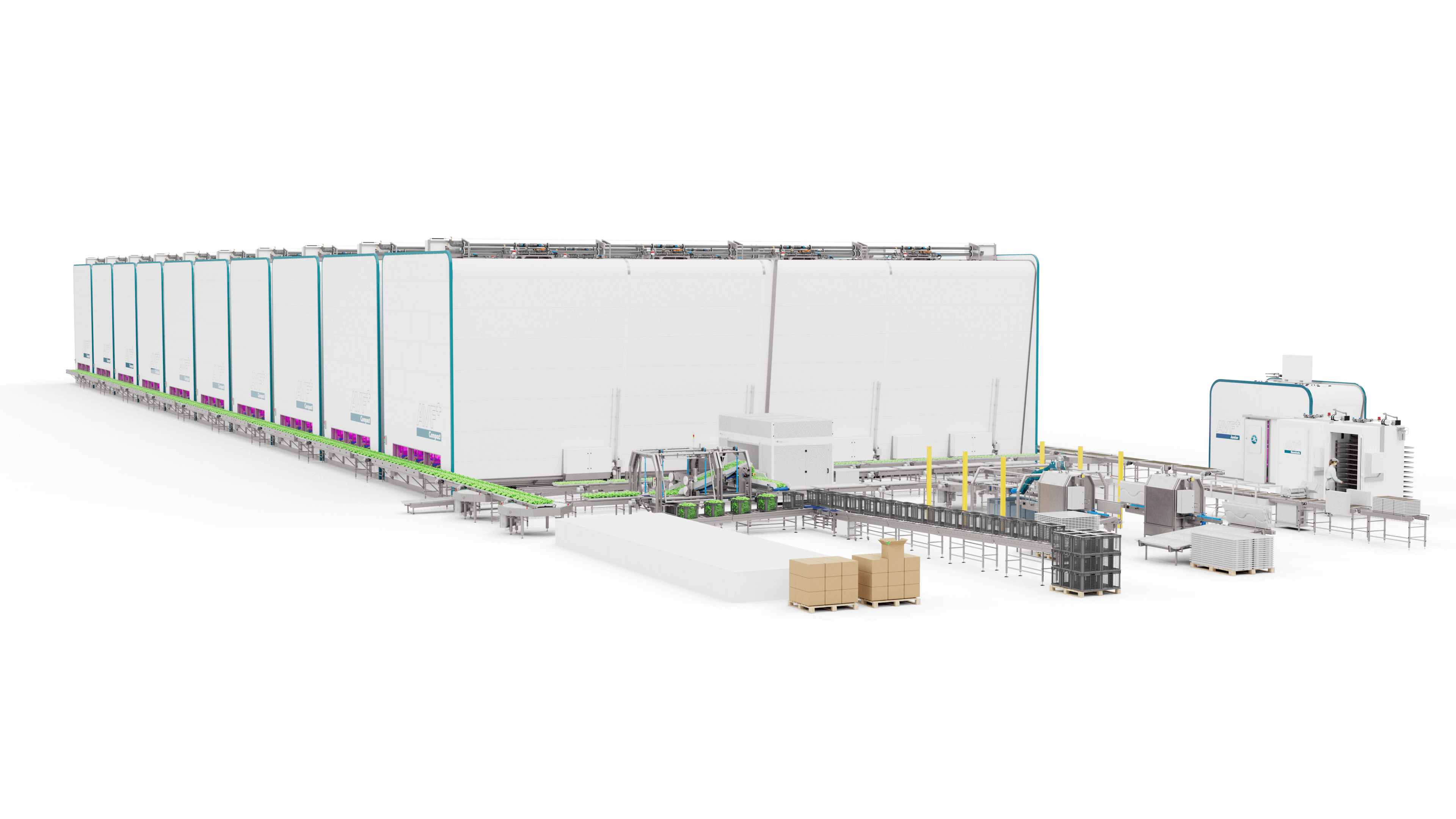

Factory 9.600

.png)

Factory 96-960

In theory, our Factories start from 96m², but in practice, it turns out that this is not viable in comparison to your operational costs. Therefore we strongly recommend that you always start from around 960m². This often involves a manual or semi-automatic processing line.

.png)

Factory 4.800

This AVF+ Factory consists of five cells of 960m² each. From this footprint on, it is recommended to implement a fully automated processing line. This means that labor is reduced to minimal FTE. Therefore it becomes more expensive on the investment, but more cost-efficient over a longer period of time

.png)

Factory 9.600

Our automated process equipment can handle up to 10 running AVF+ Compacts without any capacity issues. If you want to expand the AVF+ Factory further, you will need to settle for additional automated process equipment.

AVF+ Factory

When we add AVF+ process equipment to your AVF+ Compact, we refer to it as an AVF+ Factory. Depending on the size and local factors, we select the best fitting manual, semi-automatic, or fully automated process equipment. Our AVF+ Factory is thus controlled by adaptive automation. Hence, depending on your business case, we look at the best option to get the most out of your AVF+ Factory.

Medium to large size vertical farm with process equipment.

Scale to your needs

Adding more growing surfaces is easier than ever, do you have a need for more cells afterward? We can add cells up to a total of 10,000 meters of cultivation area without any problem.

Building needs

The first step towards an AVF+ Factory is a suitable building. For example, two cells (960m²) with processing equipment and a water irrigation area require a minimum of 1,000 to 1,200 square meters of footprint.

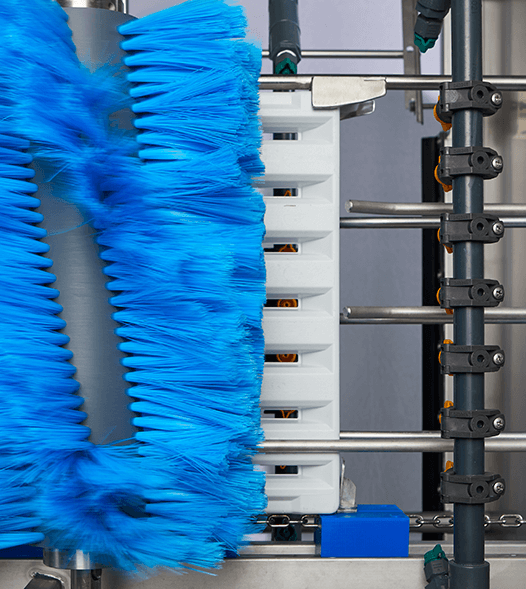

Sensible automation

Operating an AVF+ Factory requires labor, depending on your business case we advise manual, semi-automated, and fully automated processing equipment. In order to achieve the highest possible ROI.

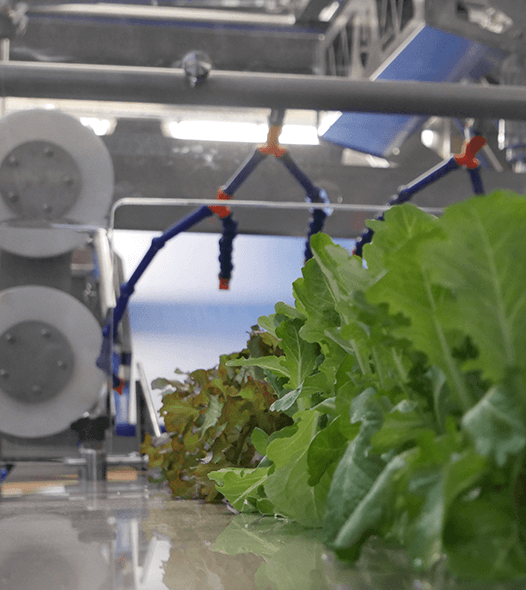

From seeding to packaging

We deliver a turn-key Automated Vertical Farming facility from A to Z. You just have to provide us a suitable building and profitable market, and we make sure you can be a grower too!

.png?width=526&height=588&name=4%20op%20een%20rij%20Factory%201%20(1).png)

Be a professional grower with the AVF+ Factory

With AVF+ Factory, everyone can be a grower. You only have to provide us a suitable building and market opportunity, and we provide you with a turn-key fully automated vertical farming Factory. Growing any type of crop has never been so easy.

The AVF+ Factory is also ideal for pursuing large volumes of automated crop production. All the best of AVF+ is combined into a complete system. With the AVF+ Factory, all your cultivation dreams come true.

Feature #1

From seeding to packaging

Feature #2

Growing your -for example- lettuce under one roof

Feature #3

Growing crops

Type of crops

you can grow with us

.png?width=384&height=244&name=pngwing.com%20(13).png)

Lettuce

Learn more

Leafy Greens

Learn more

Herbs

Learn more

Mircogreens

Learn more

Young Plants - Softfruit

Learn more

Young Plants - Ornamentals

Learn more

Young Plants - Forestry

Learn more

Bio-Science

Learn more

Let us tell

You more.

- Get in touch with Artechno Growsystems

- Learn more about Automated Vertical Farming

- And any other questions

Compare this AVF+ product

Discover all the Features