Growing the Future of BioTech

Unlocking the potential of Plant Molecular Farming

Plant Molecular Farming is revolutionizing biotechnology by using plants to produce complex, safe, and scalable biomolecules. With our systems, plants can be grown under perfectly controlled conditions—ensuring consistency, purity, and scalability that traditional agriculture cannot match.

Biotechnology, through plant molecular farming, is revolutionizing the production of high-value proteins for medicines by using genetically engineered plants as “bio factories.”

At Artechno Growsystems, we enable the future of biotech by Multilayer Precision Cultivation (MLPC) systems tailored for Plant Molecular Farming (PMF). Our technology empowers researchers and biotech companies to cultivate plants as reliable bio factories, producing high-value compounds for cutting-edge medical and scientific applications.

Why CEA & Multilayer Cultivation?

- Scalable, GMP-ready infrastructure

- Turnkey agroinfiltration solutions

- End-to-end facility design and deployment

- Regulatory, engineering and scale-up support

The Artechno Advantage

With our expertise in plant cultivation systems, Artechno Growsystems bridges the gap between biotechnology and plant science. We deliver turnkey growth solutions that:

- Ensure batch-to-batch consistency

- Enable rapid scaling from research to commercial production

- Reduce environmental footprint compared to traditional production methods

- Provide a sustainable, plant-based alternative to animal or cell culture systems

By combining technology, biology, and sustainability, Artechno Growsystems helps companies grow the next generation of biopharmaceuticals—inside plants.

PMF applications cover 6 areas

Plant molecular farming enables the cost-effective, large-scale, and safe manufacture of complex biologicals, achieving high purity and scalability that traditional systems often cannot match.

1. Gene therapies / AAV Vectors

Producing viral vectors with plant-based precision.

Plants can be harnessed to produce viral vectors, such as adeno-associated virus (AAV) used in gene therapy. The plant-based expression platforms allow for the scalable manufacturing of viral capsid proteins, which are vital for packaging therapeutic genetic material. Using plants can reduce contamination risks, lower production costs, and streamline the production of personalized gene therapy products.

2. Vaccines

Safe, scalable platforms for next-generation vaccine production.

Plant-based systems are increasingly used to produce vaccines, including protein subunits and virus-like particles. This platform is notable for responding rapidly to pandemics—plants can be genetically programmed to express vaccine antigens within weeks. For example, Medicago’s Covifenz COVID-19 vaccine is a plant-derived product. Plant molecular farming is also being explored for edible vaccines and personalized immunizations, offering unique delivery and customization advantages for both human and veterinary use.

3. Growth factors (e.g. FGF-2)

Reliable biomolecule production for regenerative medicine.

Growth factors such as Fibroblast Growth Factor-2 (FGF-2) are crucial for cell therapy and tissue engineering. Plants’ post-translational modification capabilities enable them to produce biologically active, human-like growth factors. This avoids the contamination risks posed by mammalian cells and permits affordable, large-scale growth factor production.

4. Monoclonal Antibodies (mAbs)

Plant-derived antibodies for therapeutic use.

Monoclonal antibodies treat cancer, autoimmune diseases, and infections. Plant-made mAbs can be produced rapidly and affordably, especially important for epidemic response. Plants can perform advanced glycoengineering, producing antibodies with tailored efficacy and safety. This has led to the creation of therapies such as ZMapp for Ebola. As regulatory frameworks mature, plant-produced therapeutic antibodies are expected to become increasingly mainstream.

5. Recombinant collagen

Sustainable, animal-free collagen production.

Collagen is widely used in medicine and cosmetics. Producing recombinant collagen in plants circumvents risks associated with animal-derived sources (e.g., viruses, prions), enabling a pure and consistent product. Plants provide the proper machinery for the assembly and post-translational modification of recombinant collagen, addressing the growing demand for safe and sustainable sources.

6. Other API's

Other Active Pharmaceutical Ingredients. Expanding the toolbox of plant-based biomanufacturing.

Beyond biologics, plants can express a range of APIs otherwise obtained from rare, expensive, or unsafe sources. This includes blood-clotting factors, enzymes, and other specialized proteins used in medicine. The approach is scalable and inherently safe from human pathogen contamination, making it ideal for both established and emerging biopharmaceutical needs.

Producing High-Value Proteins from Plants

Together with our customers, we are pioneering large scale production of high-value proteins using plant-based platforms. Our recent trials with Nicotiana benthamiana have demonstrated the remarkable potential of this plant as a biofactory, yielding proteins of exceptional quality and consistency.

These experiments confirm that plants can reliably produce complex biomolecules, including therapeutic proteins, at scales suitable for research and commercial applications. Leveraging our Multilayer Precision Cultivation systems, we can precisely control growth conditions—light, temperature, humidity, and nutrients—to optimize protein expression while ensuring reproducibility and GMP-compliance. This approach not only accelerates development timelines but also offers a sustainable, plant-based alternative to traditional cell culture or animal-derived production methods, opening new opportunities in biopharmaceutical manufacturing.

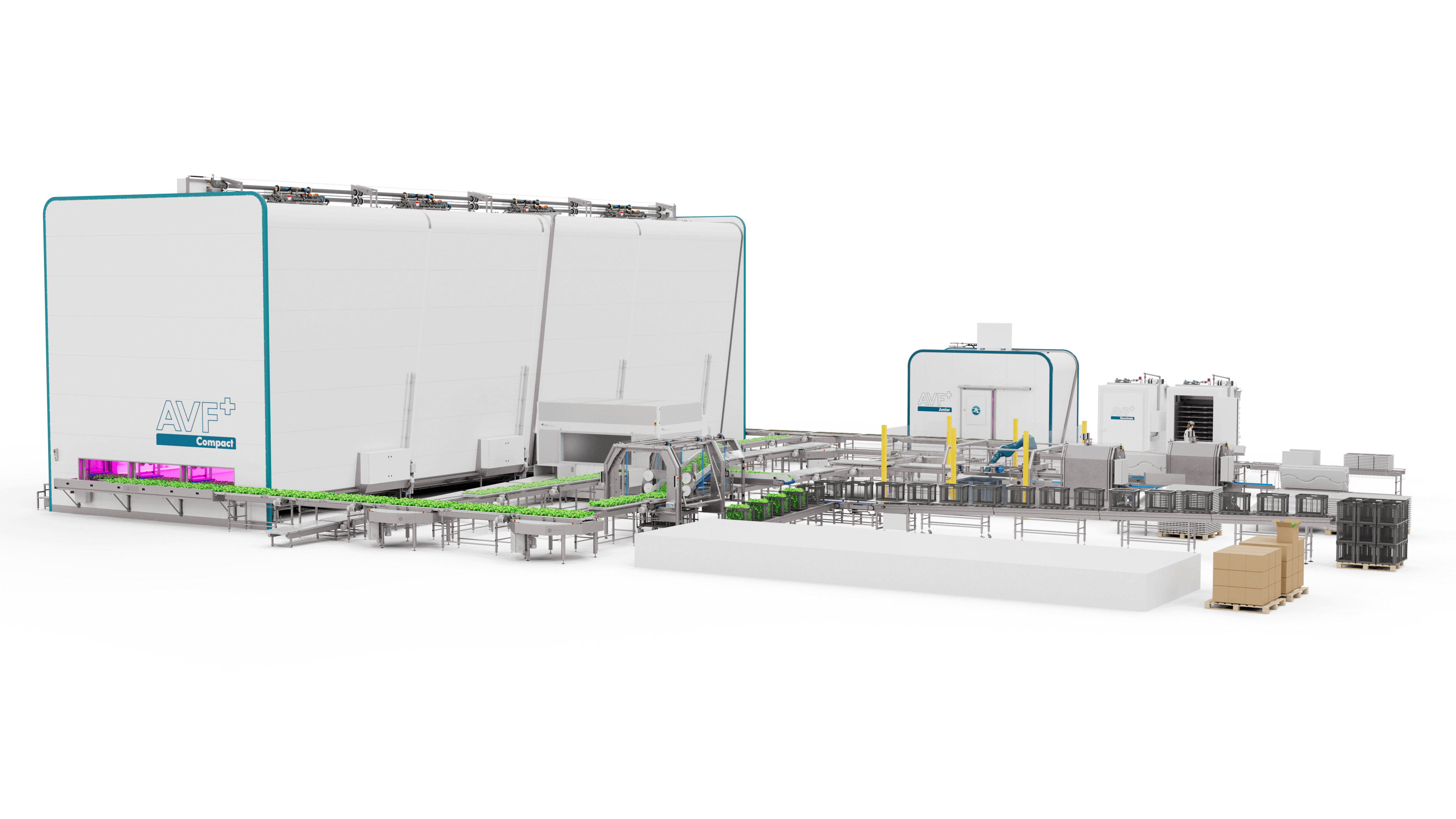

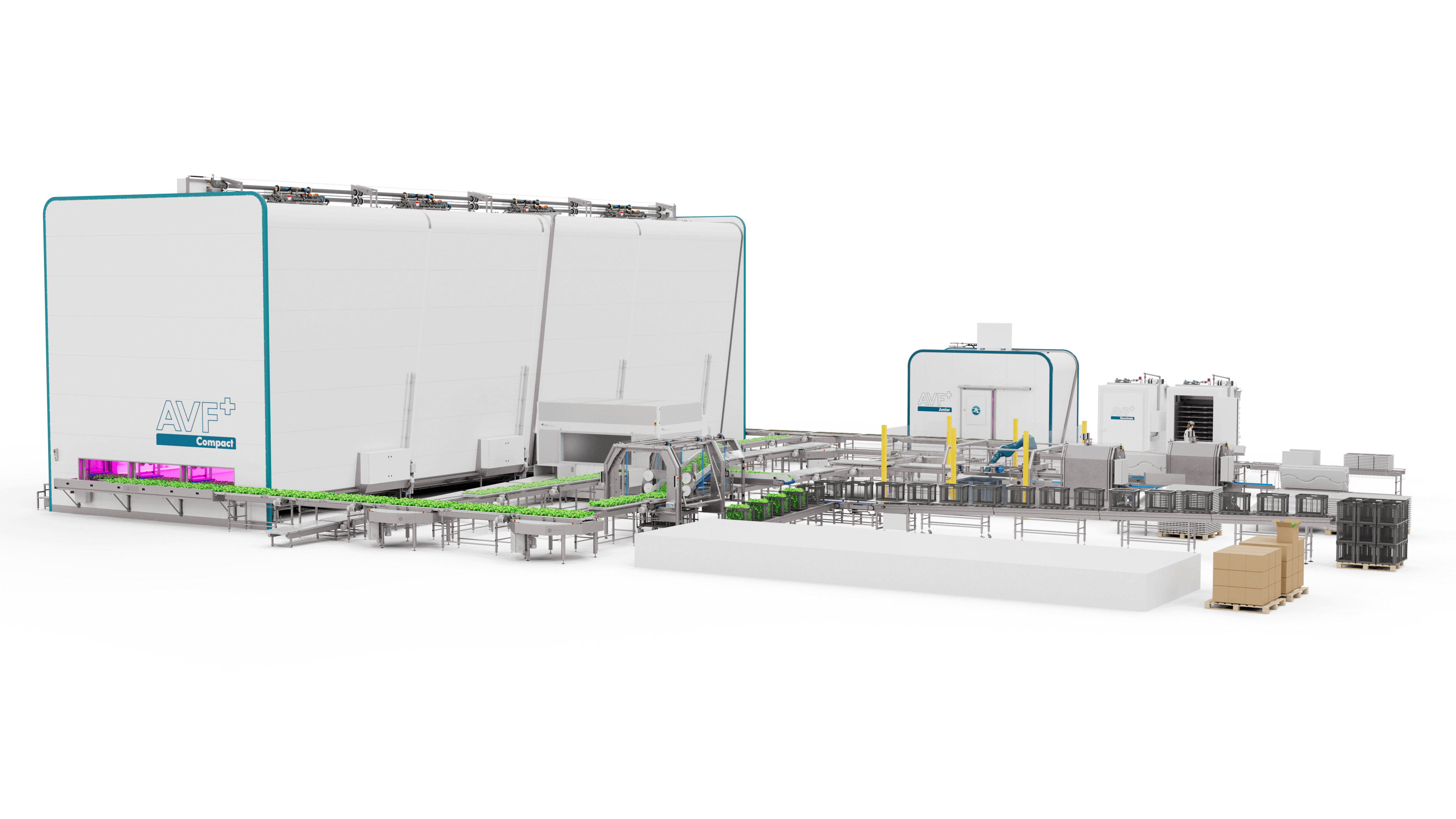

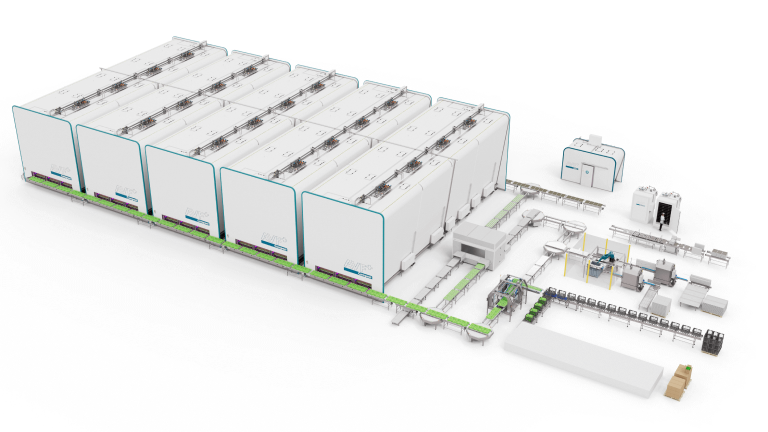

Facility configurations

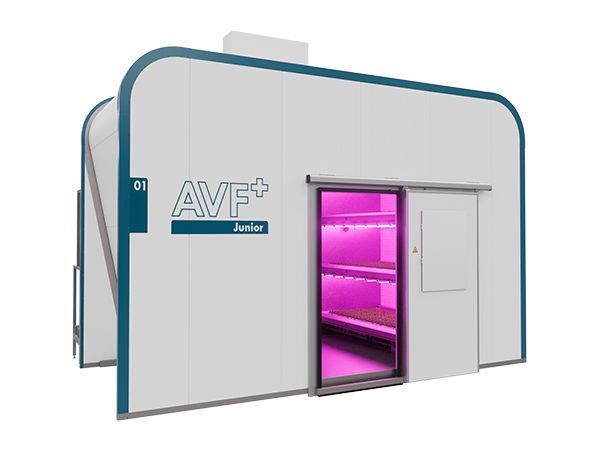

R&D

Manual lab

Semi-Automated

Pilot Facility

Features:

- Manual agroinfiltration and batch processing for flexible experimentation.

- Supports small-scale protein production and process optimization.

- Modular design allows for straightforward expansion as needs evolve.

Best Suited For: Startups, academic laboratories, and early-stage R&D teams.

Features:

- Automated agroinfiltration with batch processing to enhance consistency.

- Scalable production lines suitable for pilot-scale manufacturing of proteins and therapeutics.

- Regulatory-compliant clean room configurations.

Best Suited For: Organizations aiming to validate processes before full GMP-compliant production.

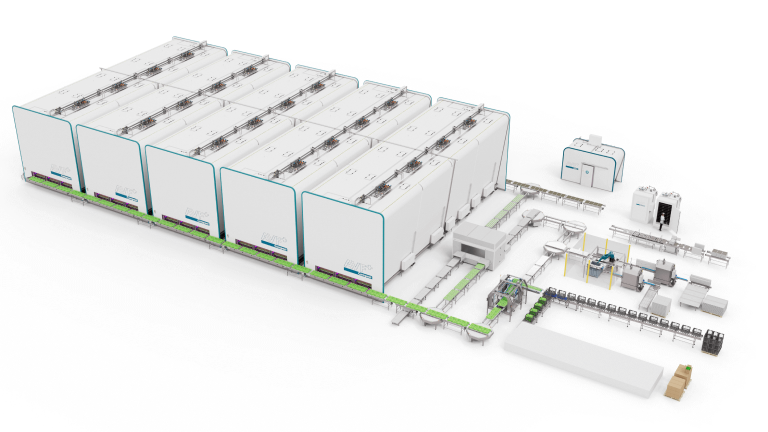

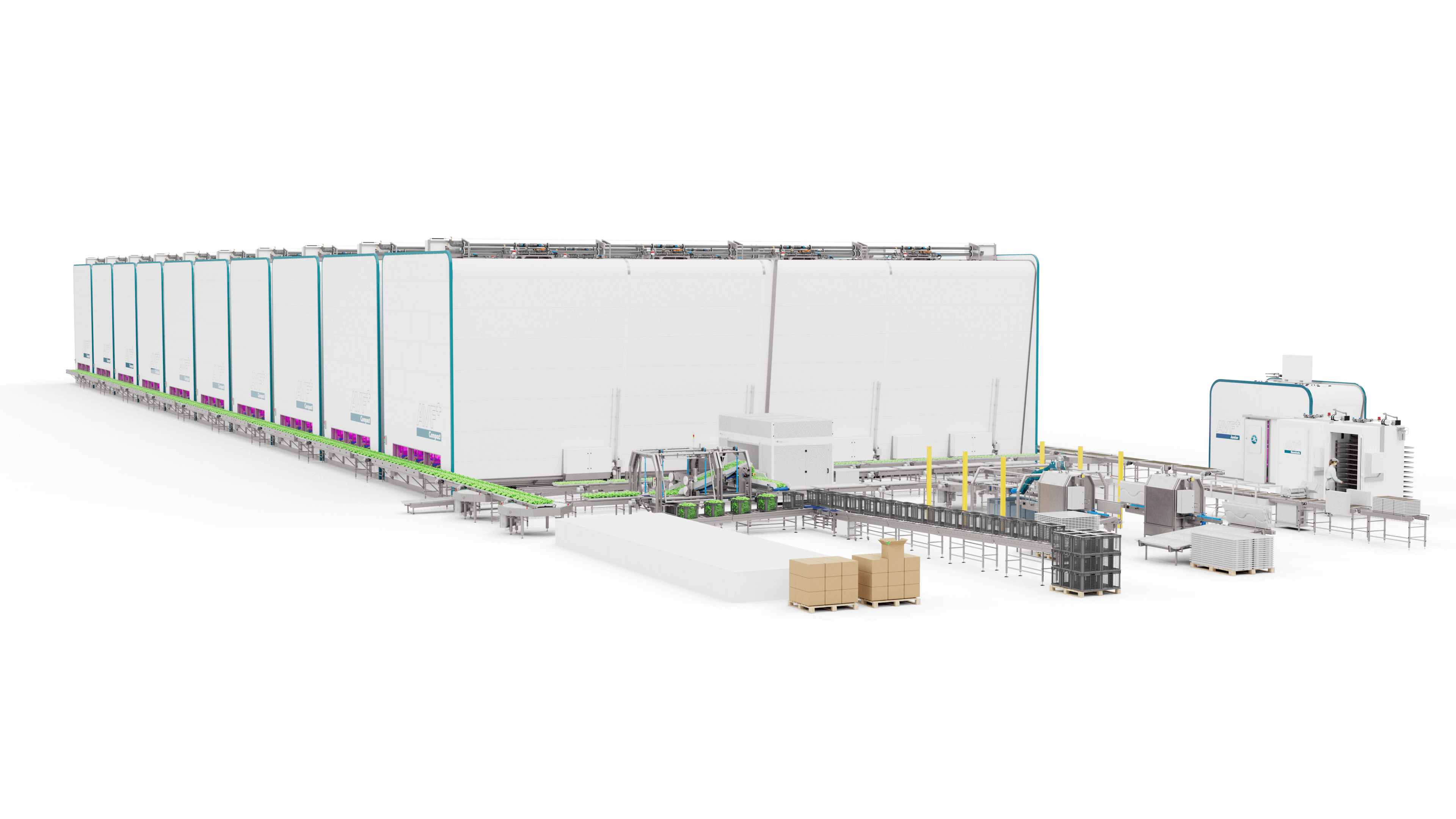

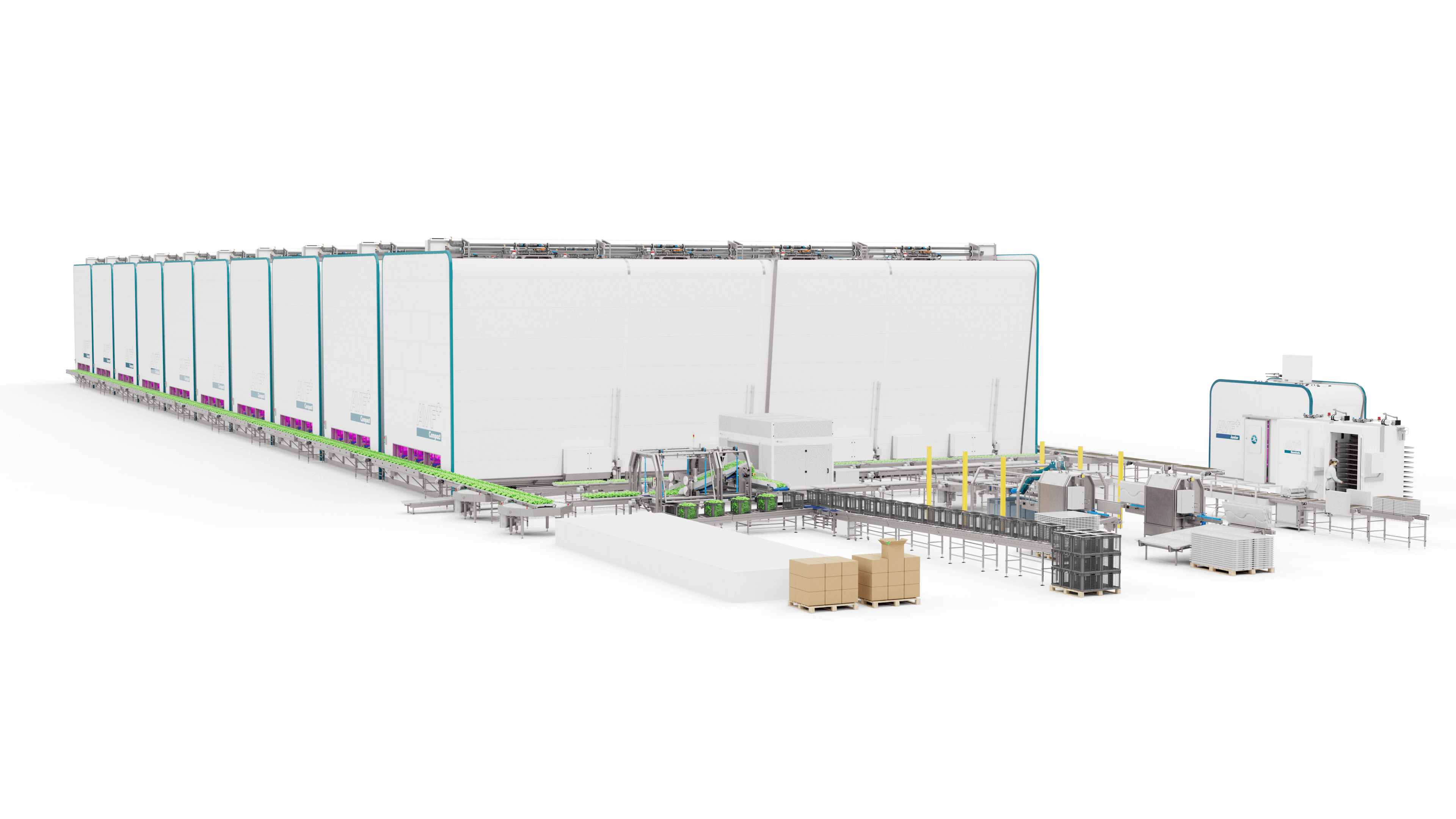

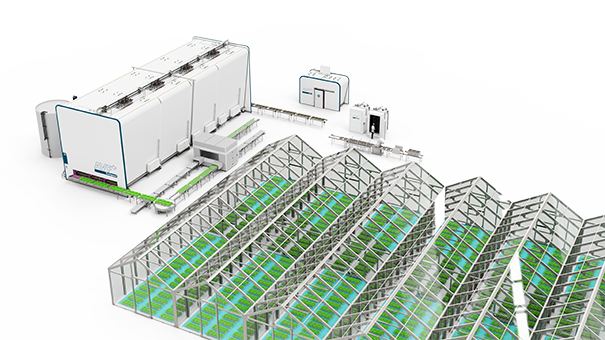

Commercial

Fully automated

Hybrid Automated

Greenhouse

Features:

- Comprehensive automation encompassing agroinfiltration, plant cultivation, and harvesting.

- Advanced plant growth systems designed for maximum efficiency.

- GMP-certified facility layouts prepared for regulatory approval.

- Scalable bioreactors and purification systems for large-scale protein extraction.

Best Suited For: Companies progressing to commercial-scale production of biologics.

Features:

- Greenhouse-integrated automated agroinfiltration systems.

- Climate-controlled precision farming to enhance plant growth.

- Energy-efficient operations through a hybrid indoor-outdoor approach.

- Configurable for both GMP-compliant and non-GMP biomanufacturing processes.

Best Suited For: Large-scale producers seeking a balance between automation, cost-efficiency, and sustainability.

Let us tell

You more.

- Get in touch with Artechno Growsystems

- Learn more about Automated Vertical Farming

- And any other questions

Compare this AVF+ product

Discover all the Features